The tell tale signs of an Nvidia graphics chip failure were obvious and patently apparent immediately. We were present with vertical grey lines and intermittent blurring of the Apple logo. After just five minutes of attempting too boot the fan was blowing at full speed and exiting very hot air after only minimal operation.

|

| Apple iMac A1225 with frozen display |

our attack plan was to first reseat the graphics chip and reapply thermal paste while removing any blockages of the fan. We also have our ace card in the form of a new rework station the ACHI IR 6500. We would prefer not to have to resort to such extreme measures if its not absolutely necessary.

|

| ACHI Model IR 6500 rework station. |

We start as always by removing the glass panel, the glass on modern iMacs is held in place with magnetic blocks contained throughout the outer edge, We do not recommend using anything other than a suction cup to dislodge it, any other tools may scratch the glass or chip the bezel.

|

| After removing the front panel we are free to remove screws |

After removing all the screws you can easily prise the aluminium bezel away, care must be taken not to severe the sensor attached to the middle-top of the bezel. You can use a blade to dislodge it before completely pulling the frame away.

|

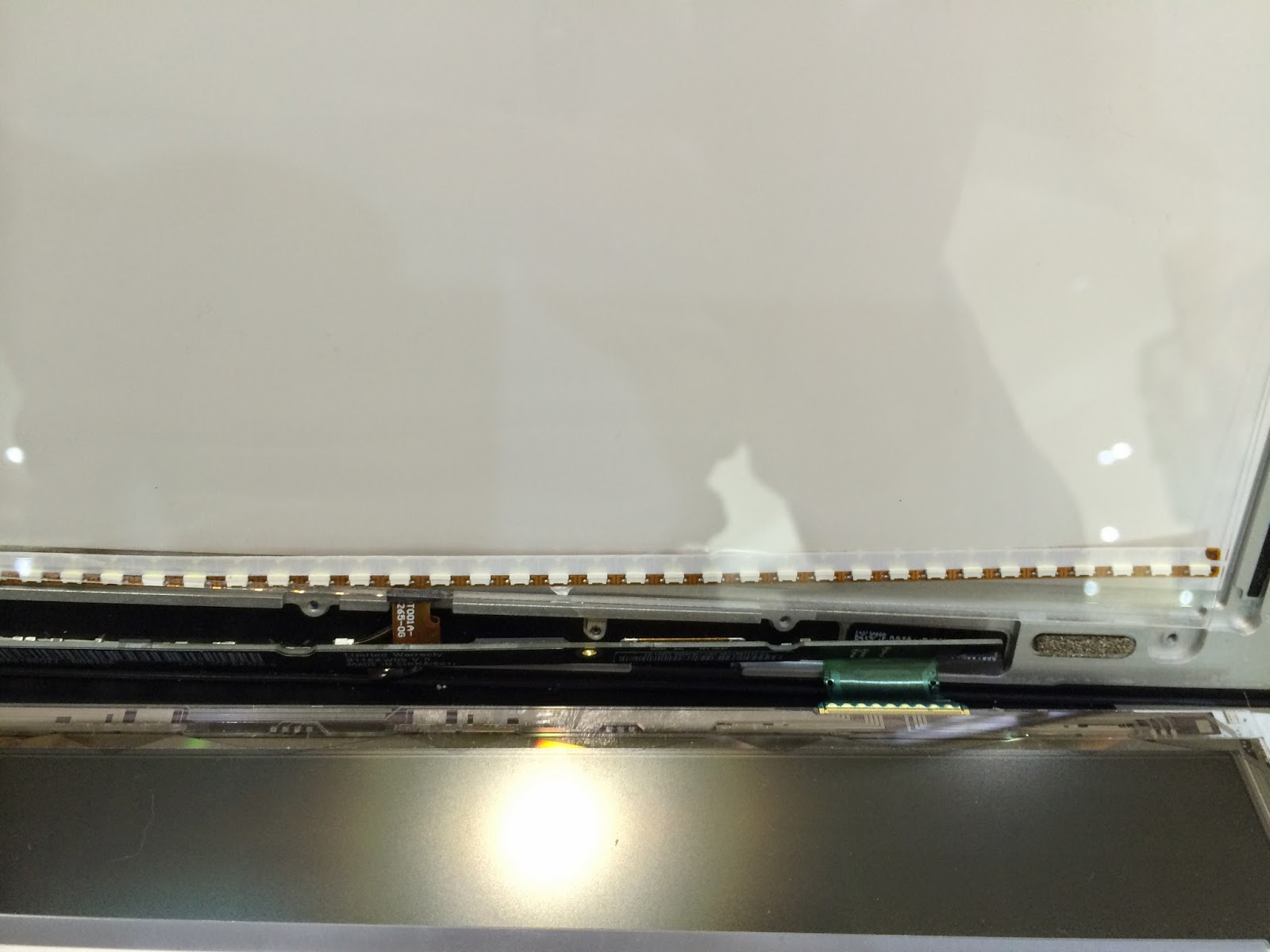

| Now we are ready to remove the LCD |

The LCD can easily be removed by lifting it forward, from there you can access the internal ribbon cables and detach each with minimal of effort. Again I would air on the side of caution when removing these as the clips are very flimsy and can easily break.

|

| LCD removed and ready for cleaning. |

Once we have remove the display its time to start cleaning the interior of any dust that has built up, I recommend some gloves as these machines tend to suck in vast quantities of germs. Have some alcoholic wipes/hand sanitiser to hand.

|

| The speakers must be removed before taking out the main board |

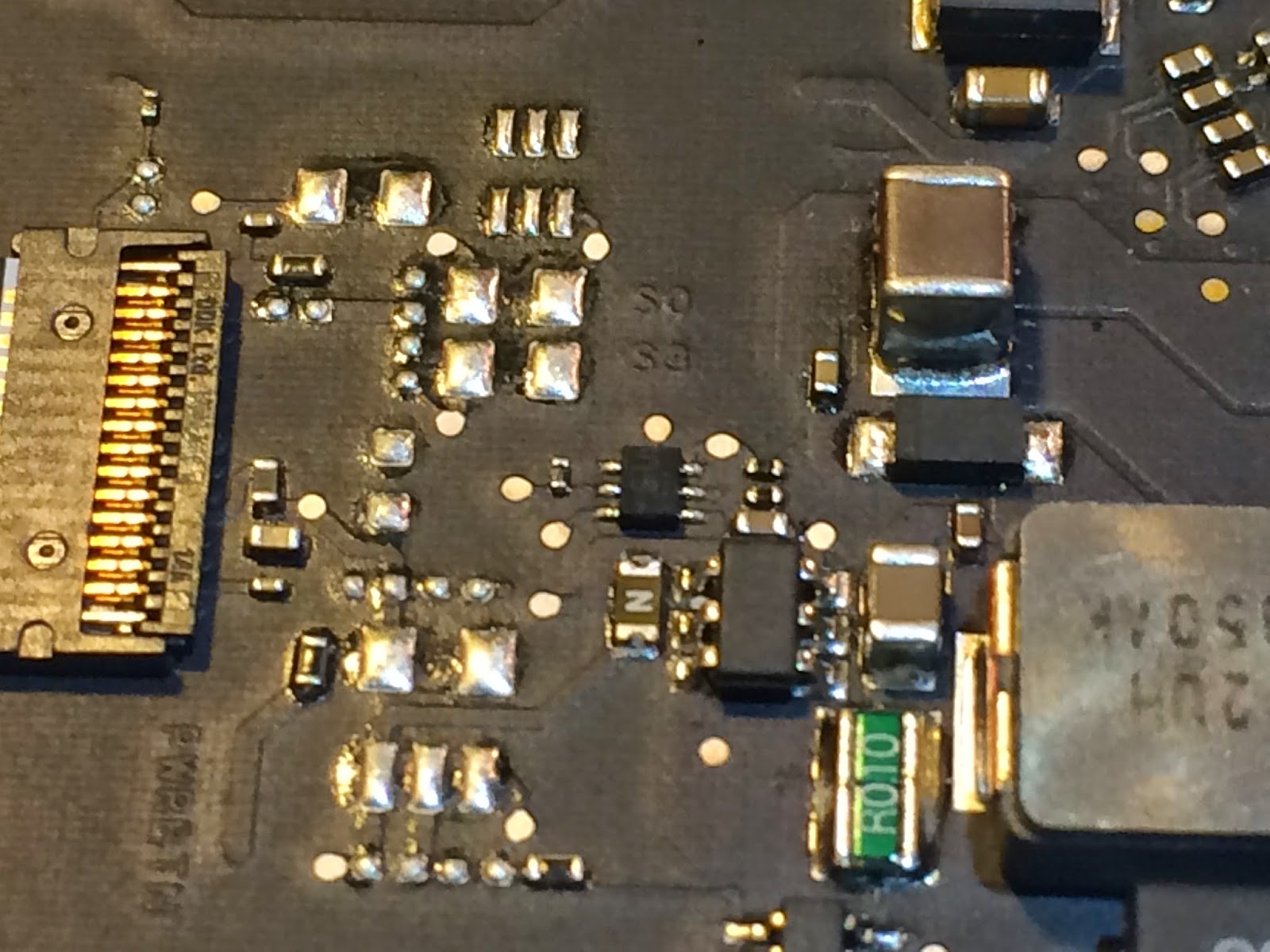

We can now start methodically removing all the screws holding the main-board in place, these are mostly torx screws so it would be a good idea to arm yourself with the correct tools, we recommend the ifixit toolkit.

|

| removal of screws is cumbersome yet very easy |

Once we have detached all flex ribbons its fairly straight forward to start prising the main board away from the chassis.

|

| removal of main board only requires gentle tugging |

after removing the man board, you are free to clean up the rest of the dust and start removing the big heat sink that's held in place by you guessed it yet more torx screws.

|

| heat sink removal - easy as pie. |

We are now ready to reapply thermal compound, while you're in you might as well do the CPU block. We use Arctic Silver.

Were fairly confident this should have cured the problem, lets boot her up to see what happened

First boot after partial reassembly, indeed we were right, the Mac now boots fully, another happy customer no doubt. I originally created this blog to help the company I worked for, they are useless and I do not recommend them, take your Apple Mac to mac repair ltd - Leeds, in Chapel Allerton.